- FANUC IR VISION ERROR PROOFING SOFTWARE

- FANUC IR VISION ERROR PROOFING PROFESSIONAL

- FANUC IR VISION ERROR PROOFING SERIES

The drive motor is a proven FANUC high torque servo motor with a pulling capacity suitable for unassisted wire feeding from conventional spools or pay-off packs. The design is optimized to feed aluminum and soft wire.

FANUC IR VISION ERROR PROOFING SERIES

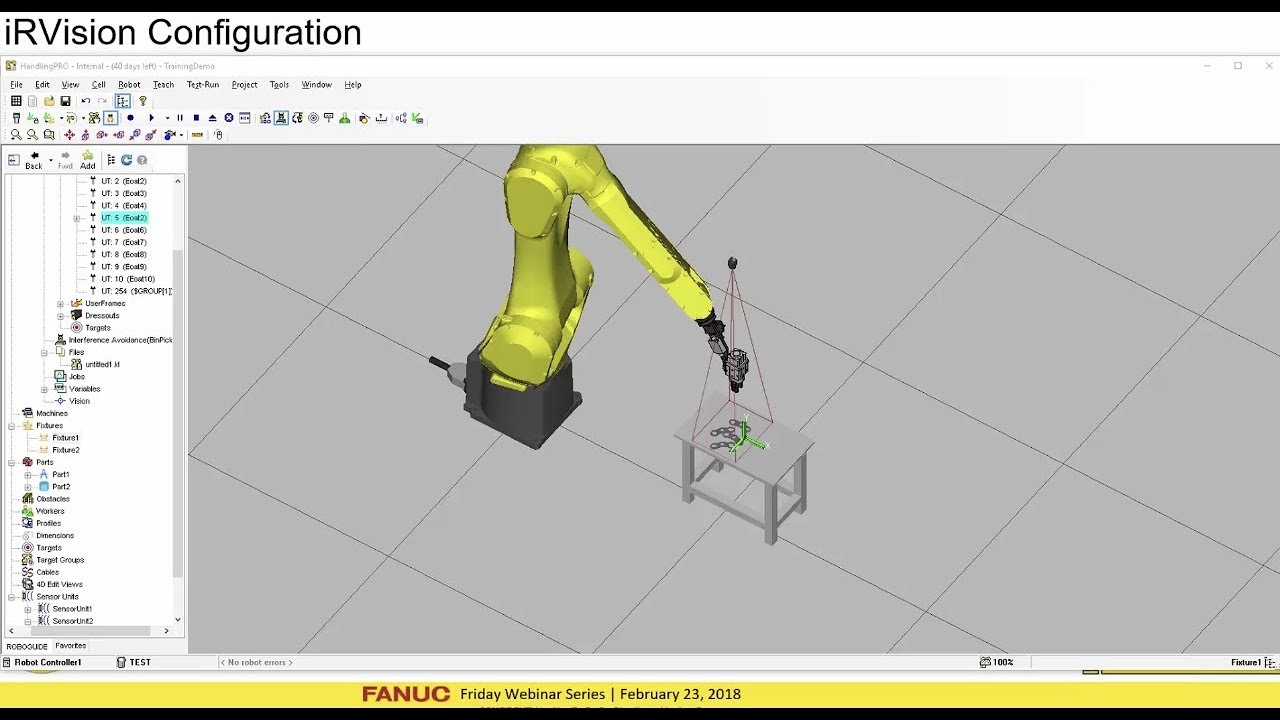

Using these systems, adaptive welding, seam tracking, automated inspection of joining processes as well as other processes can realize increased reliability and effectiveness of the overall operation.įANUC Robotics' ServoTorch is a fully-integrated, servo-controlled, wrist-mounted, four-roll (4) "Pull" wire feeder controlled by the ARC Mate® series robots. It provides a 2-D or 3-D robot guidance and/or error proofing tool to accomplish part location, presence detection and other operations that normally require special sensors or custom fixturing.Īs a FANUC Certified Vision specialist, Lincoln Electric provides expertise in implementing vision into welding applications and can assist you with the application knowledge, skill and training.Ĭombining Lincoln Electric Automation’s welding and cutting proficiency with 3-D laser vision techniques and advanced sensing devices produces precise, efficient and reliable systems for customer applications. IRVision™ is a ready-to-use robotic vision system that requires no additional hardware except for a camera or sensor and a cable. Built on our industry-leading bin picking algorithm, our Flexfeeder overcomes the high cost of tradition parts feeding.

FANUC IR VISION ERROR PROOFING SOFTWARE

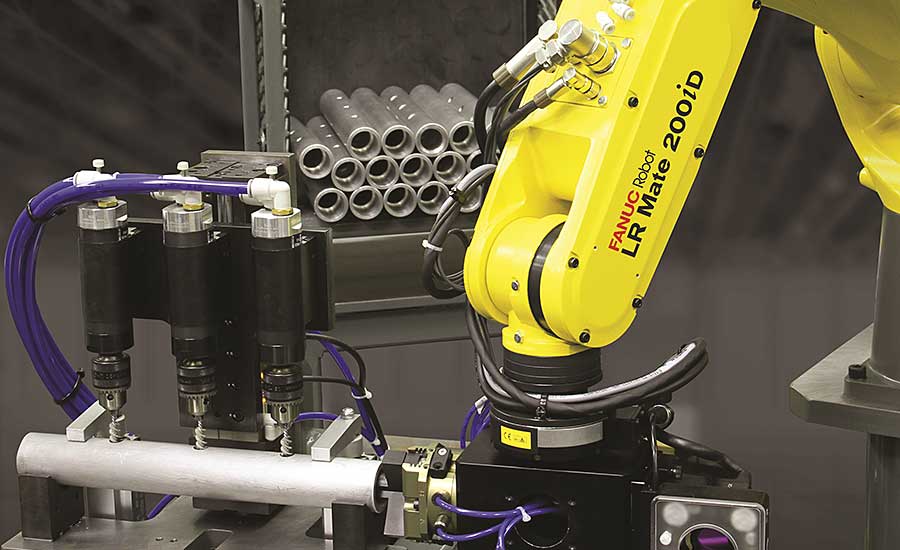

They also feature built in software for error proofing so manufacturers can be. FANUC Robotics’ new Flexible Feeder is the next generation in part feeding technology. The vision system tells the Equator what part number is being presented and what measurement program to run. These products provide a level of performance, reliability and cost effectiveness unmatched by third-party solutions. complex 2D and 3D workpieces with FANUCs robot vision system, iRVision. Now Buck and Wardell are assembling a cell that consists of two Equators, a Fanuc LRMate 200iC six-axis robot, multiple lanes of low-profile conveyor, a Fanuc iR vision system, and an ATI quick tool-changer for the robot’s end-effectors. Robotic vision provides the intelligence required for successful dynamic manufacturing processes and robust robotic applications.

These options have their own benefits and limitations, and only with a thorough evaluation of each application can a user determine which system can provide the most return on investment in terms of increased productivity and improved quality. PLC troubleshooting knowledge (Rockwell), Fanuc and ABB robot programming knowledge.

FANUC IR VISION ERROR PROOFING PROFESSIONAL

Lincoln Electric Automation employs an experienced and professional staff to assist with any application review. For any robotic application, there are options to help improve weld quality and repeatability.

0 kommentar(er)

0 kommentar(er)